Reducing manufacturing waste by 15% isn’t about incremental tweaks; it requires a strategic overhaul of key processes and targeted technology adoption.

- Modernizing legacy equipment and implementing predictive maintenance offers a direct and measurable ROI by slashing energy costs and unplanned downtime.

- Applying lean principles to high-mix production and leveraging hybrid prototyping (3D + CNC) increases agility and dramatically cuts material waste.

Recommendation: Start with a comprehensive ROI analysis for retrofitting before deploying any new technology to ensure investments align with financial and sustainability goals.

For factory managers, the pressure to cut costs while meeting increasingly stringent sustainability standards has never been higher. Faced with volatile energy prices, supply chain disruptions, and ESG mandates, the directive to “reduce waste” has evolved from a simple operational goal to a critical strategic imperative. The common advice—”implement lean manufacturing” or “embrace Industry 4.0″—often feels abstract and disconnected from the financial realities of running a plant. These buzzwords offer little guidance on where to start or how to justify the significant capital expenditure involved.

The fundamental challenge is that most waste isn’t visible on a spreadsheet as a line item. It manifests as hidden process friction: excess energy consumption from outdated machinery, lost production time from unplanned downtime, and material losses from imprecise tooling. The key to unlocking a 15% or greater reduction in waste lies not in chasing every new technology, but in adopting a data-driven, ROI-first approach. It’s about turning sustainability from a compliance burden into a direct financial gain by making targeted investments where the impact is greatest.

This guide moves beyond theory to provide a technical roadmap for modernizing production. We will dissect the most significant sources of waste in a modern factory and present concrete, financially justifiable strategies to address them. From calculating the true cost of legacy equipment to leveraging advanced predictive maintenance, each section provides the engineering-level detail needed to build a compelling business case for change and execute a successful transformation.

This article provides a detailed engineering perspective on modernizing production. Explore the sections below to identify the most impactful strategies for your facility.

Summary: A Factory Manager’s Guide to Strategic Waste Reduction

- Why Legacy Machinery Is Costing More in Energy Than a Modern Retrofit?

- How to Apply Lean Principles to a Low-Volume High-Mix Production Line?

- 3D Printing vs. CNC Machining: Which Is Best for Prototyping in 2024?

- The Inventory Mistake That Halts Production Lines for Days

- How to Schedule Factory Shifts to Reduce Accidents and Fatigue?

- Augmented Reality vs. Virtual Reality: Which Is Better for Industrial Training?

- Why Reliance on Grid Power Is Becoming a Strategic Risk for Factories?

- Advanced Predictive Maintenance: How to Cut Unplanned Downtime by 50%?

Why Legacy Machinery Is Costing More in Energy Than a Modern Retrofit?

The most significant source of hidden cost in many facilities is not labor or materials, but the energy consumed by aging machinery. Legacy equipment, even if fully depreciated, represents a major strategic and financial liability. These machines were designed in an era of lower energy costs and less stringent environmental standards. As a result, they suffer from poor energy efficiency, higher material waste due to lower precision, and increased unplanned downtime, creating significant process friction that directly impacts the bottom line. The argument to “run it until it dies” ignores the compounding daily cost of this inefficiency.

A modern retrofit, or a targeted replacement, is not merely a capital expense but a strategic investment with a clear and calculable return. The ROI extends beyond simple energy savings. Modern systems with improved sensors and controls reduce material scrap, while their higher reliability cuts costly unplanned downtime. Furthermore, meeting ESG (Environmental, Social, and Governance) compliance standards is increasingly tied to a company’s ability to secure financing and win contracts. A factory powered by inefficient legacy equipment is a factory with a growing risk profile. The first step in any modernization effort must be a rigorous financial analysis that contrasts the “do nothing” scenario with the quantifiable benefits of a retrofit.

Action Plan: Financial Model Variables for Retrofit ROI Calculation

- Calculate current energy consumption baseline (kWh per production unit).

- Factor in energy savings potential (typically 20-30% reduction).

- Include reduced material waste from higher precision (5-10% improvement).

- Quantify decreased unplanned downtime (average 35-50% reduction).

- Account for potential carbon tax liabilities and ESG compliance costs.

How to Apply Lean Principles to a Low-Volume High-Mix (LVHM) Production Line?

A common misconception is that lean manufacturing principles are only effective in high-volume, low-mix environments like automotive assembly lines. For factories producing a wide variety of products in smaller batches (LVHM), the traditional focus on repetitive task optimization can seem irrelevant. The key to applying lean in an LVHM context is to shift the focus from optimizing the product flow to optimizing the process flexibility itself. The primary sources of waste here are not overproduction, but waiting (changeover time) and transportation (inefficient facility layout).

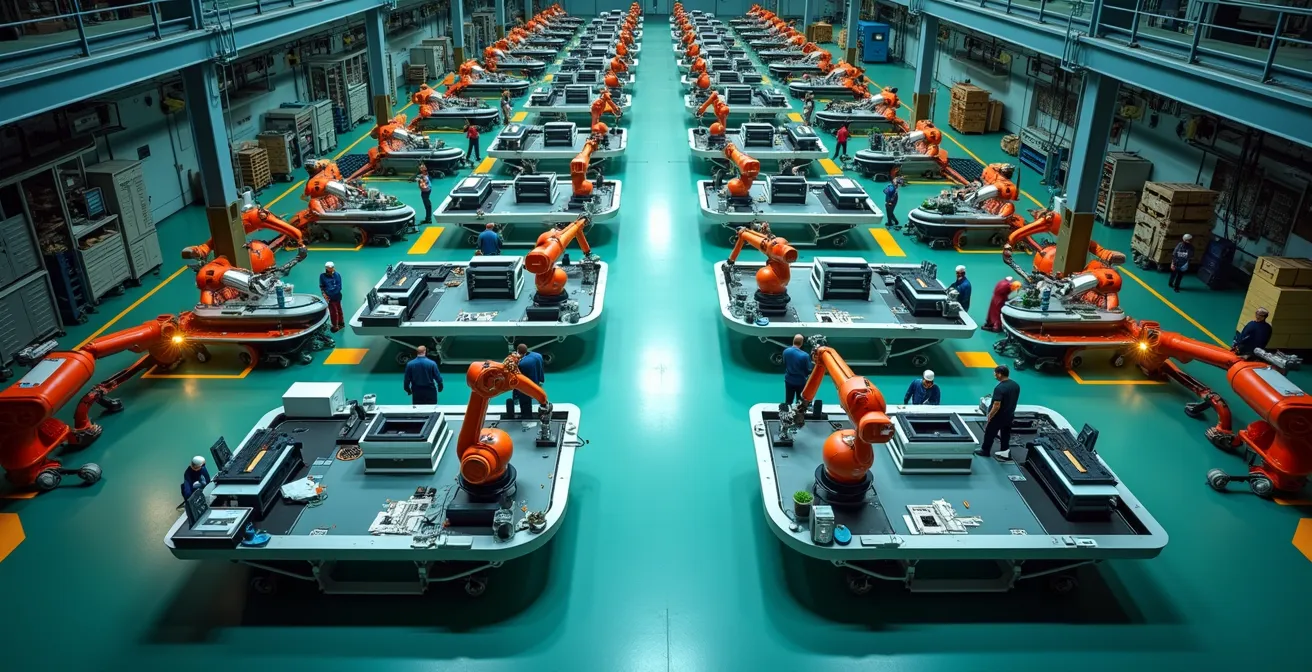

The solution lies in redesigning the production floor around modular production cells instead of a linear assembly line. Each cell is a self-contained, multi-functional unit equipped with the necessary tools and cross-trained personnel to complete a significant portion of the manufacturing process. By using mobile workstations, flexible power connections, and optimized tool carts, these cells can be rapidly reconfigured to handle different product variants. This approach directly attacks changeover time by treating the ‘changeover’ as a process to be optimized, just like any other production step. As one case study shows, this focus on flow diagramming and modular design can drastically reduce transport and waiting waste, enabling the agility required for LVHM.

As this layout demonstrates, modular cells create self-sufficient “islands of productivity” that can be rearranged to accommodate diverse workflows. This physical agility is the cornerstone of lean implementation in a high-mix environment, allowing for rapid adaptation without the bottlenecks of a fixed, linear system. Success depends on empowering small teams within each cell to manage their own workflow and continuously improve their changeover processes.

3D Printing vs. CNC Machining: Which Is Best for Prototyping in 2024?

In the quest to reduce development waste, the choice between additive manufacturing (3D printing) and subtractive manufacturing (CNC machining) for prototyping is a critical decision point. Each technology has distinct advantages and is best suited for different stages of the product development lifecycle. 3D printing excels in speed and low material waste for early-stage iterations, while CNC machining provides high-fidelity, functional prototypes using production-grade materials. Choosing the wrong method can lead to wasted time, materials, and misleading test results.

The following table outlines the key operational differences, providing a clear framework for selecting the appropriate technology based on the specific prototyping goal.

| Criteria | 3D Printing | CNC Machining |

|---|---|---|

| Iteration Speed | 24-48 hours | 3-5 days |

| Material Waste | 5-10% | 30-60% |

| Prototype Fidelity | Low to Medium | High |

| Material Options | Limited polymers/resins | Production-grade metals/plastics |

| Setup Time | 15-30 minutes | 2-4 hours |

| Best Use Case | Form/fit testing, early iterations | Functional testing, late-stage validation |

However, the most advanced engineering teams are moving beyond a simple “either/or” decision. They are adopting a hybrid strategy that leverages the strengths of both technologies to minimize waste across the entire prototyping phase. This forward-thinking approach recognizes that the two processes can be complementary, not just competitive. As noted by industry experts, this synergy represents the next level of efficiency. The “Advanced Manufacturing Technology Review” highlights this evolution:

The hybrid strategy is the most advanced approach: using 3D printing to create custom, low-cost jigs and fixtures that dramatically speed up the setup time for CNC machines.

– Industry 4.0 Manufacturing Report, Advanced Manufacturing Technology Review

The Inventory Mistake That Halts Production Lines for Days

While excess inventory is a well-known form of manufacturing waste, the most catastrophic inventory-related failure is not overstocking, but a sudden, unexpected stockout of a critical component. This often stems from a reliance on outdated tracking methods, leading to “ghost inventory”—stock that exists in the ERP system but is physically missing, expired, or non-conforming. The financial impact of this error is immense, with a recent report indicating that $163 billion of inventory perishes or is discarded annually worldwide. A single missing bin of specialized fasteners or a spoiled batch of resin can halt a multi-million dollar production line for days, creating massive downtime waste that dwarfs the cost of the inventory itself.

Preventing this requires moving from periodic manual counts to a system of real-time digital inventory tracking. This is not just about knowing what you have, but where it is, how old it is, and whether it meets quality standards at any given moment. Implementing such a system provides the end-to-end visibility needed to eliminate ghost inventory and enforce critical process controls like First-In-First-Out (FIFO). The implementation process is systematic and technology-driven:

- Conduct a comprehensive inventory audit to identify and reconcile all ghost inventory.

- Implement QR code or RFID tagging on all bins, pallets, and raw materials.

- Link the new tracking system directly to the central ERP for real-time visibility across departments.

- Enforce First-In-First-Out (FIFO) or First-Expired-First-Out (FEFO) protocols through automated system controls.

- Set up automatic system alerts for low stock levels, upcoming expiration dates, and non-conforming batches.

By digitizing inventory management, a factory transforms its supply chain from a reactive liability into a proactive, data-driven asset, effectively eliminating one of the most disruptive forms of production waste.

How to Schedule Factory Shifts to Reduce Accidents and Fatigue?

Waste in manufacturing is not limited to materials or energy; it includes the loss of human potential due to fatigue and error. Suboptimal shift scheduling is a direct cause of increased accident rates, lower quality control, and higher employee turnover—all significant costs to the business. The traditional approach of simply rotating shifts without regard to human biology is fundamentally flawed. A more scientific approach, rooted in the principles of chronobiology, can yield dramatic improvements in both safety and productivity.

Chronobiology-based scheduling models, such as the 2-2-3 or DuPont rotating schedules, are designed to align work periods with the body’s natural circadian rhythms. These systems typically feature faster rotations and avoid isolating workers on permanent night shifts, which are known to be detrimental to long-term health and alertness. A European case study of 268 manufacturing companies demonstrates the power of this approach. By implementing these advanced scheduling models and combining them with skills matrix optimization, firms reported significant reductions in fatigue-related errors and accident rates. Aligning shift work with human physiology is a low-cost, high-impact lever for reducing waste associated with human factors.

Implementing such a system requires a shift in mindset from treating employees as interchangeable units to managing them as a high-value asset whose performance is tied to their well-being. The focus moves to creating predictable, forward-rotating schedules that allow for adequate rest and recovery. This not only reduces the risk of costly accidents but also improves morale and retention, further cutting down on the waste associated with hiring and training new personnel.

Augmented Reality vs. Virtual Reality: Which Is Better for Industrial Training?

Reducing waste from defects and rework starts with effective training. Traditional on-the-job training can be slow, inconsistent, and risky, especially when dealing with complex machinery. Augmented Reality (AR) and Virtual Reality (VR) have emerged as powerful tools to address these challenges, but they serve different purposes. Choosing the right technology is critical to maximizing training ROI and minimizing waste. VR is best for foundational, risk-free training, while AR excels at providing real-time, on-the-floor guidance.

The decision framework depends on the specific type of waste being targeted. Virtual Reality creates a fully immersive, simulated environment, making it ideal for training new hires on dangerous equipment or complex assembly processes without risking real assets or personal injury. This directly reduces waste from defects and accidents caused by inexperience. Augmented Reality, by contrast, overlays digital information onto the real world. It is best used to guide experienced workers through infrequent or complex maintenance tasks, reducing waste from motion (searching for instructions) and waiting (for expert assistance). As an industry report from IDC Research notes, this is a major area of investment, with projections that $4.1 billion will be invested in AR and VR for industrial maintenance by 2024.

This comparative table breaks down the key factors to consider when evaluating AR versus VR for your specific training needs.

| Training Aspect | Augmented Reality (AR) | Virtual Reality (VR) |

|---|---|---|

| Initial Investment | $5,000-15,000 per unit | $10,000-30,000 per station |

| Waste Reduction Focus | Motion & waiting waste | Defects & accidents waste |

| Learning Retention | 75% after 1 week | 80% after 1 week |

| Setup Time | 5-10 minutes | 15-20 minutes |

| Best Application | On-floor guidance for experienced workers | Risk-free initial training for new hires |

| Scalability | High (mobile deployment) | Medium (dedicated spaces) |

Why Reliance on Grid Power Is Becoming a Strategic Risk for Factories?

For decades, factory managers have viewed electricity as a simple operational expenditure (OpEx), with the primary goal being to secure the lowest possible price per kilowatt-hour. However, increasing grid instability, extreme weather events, and geopolitical factors are transforming grid reliance from a manageable cost into a significant strategic risk. A single blackout can halt production for hours or days, causing financial losses that far exceed any potential savings from a low electricity tariff. While a recent analysis showed that U.S. industrial electricity prices were the lowest of 24 IEA member countries, this low cost can mask the high price of unreliability.

The recent energy crisis in Europe provides a stark case study. An analysis of German manufacturing during the crisis revealed a critical divide: companies with on-site generation capabilities (such as solar, CHP, or backup generators) maintained production stability, while their grid-dependent competitors faced severe disruptions and skyrocketing costs. Energy-intensive sectors like chemicals and food products were hit hardest, with some firms seeing energy’s share of operational costs surge past 15%. This demonstrates that energy independence is no longer an environmental ideal but a core tenet of operational resilience.

Mitigating this risk involves a two-pronged strategy: aggressive energy efficiency measures to reduce overall demand (as discussed with legacy machinery retrofits) and investment in on-site generation and storage. This creates a buffer against grid failures and price volatility, turning a strategic vulnerability into a source of competitive advantage. The business case is no longer about saving on the utility bill, but about insuring the continuity of the entire production operation.

Key Takeaways

- The foundation of any successful modernization project is a rigorous ROI analysis that quantifies the total cost of legacy equipment, including energy, waste, and downtime.

- Lean principles can be effectively applied to low-volume, high-mix production by focusing on modular cell design to improve flexibility and reduce changeover times.

- Predictive maintenance is the single most powerful lever for reducing unplanned downtime, with mature implementations cutting maintenance costs by over 25%.

Advanced Predictive Maintenance: How to Cut Unplanned Downtime by 50%?

The ultimate goal of a smart factory is to eliminate unplanned downtime, the most disruptive and costly form of manufacturing waste. While preventive maintenance is an improvement over reactive repairs, the most effective strategy is Advanced Predictive Maintenance (PdM). This approach uses a network of sensors and AI-driven analytics to predict equipment failures before they happen, allowing maintenance to be scheduled during planned downtime. The financial impact is significant, with companies achieving 25-30% maintenance cost reduction and a 35-50% decrease in downtime.

Implementing a successful PdM program is a phased journey of increasing maturity. It begins with basic condition monitoring and evolves toward a fully integrated, prescriptive system.

- Level 1: Condition Monitoring: Implement basic sensors for temperature, vibration, and power consumption on critical assets.

- Level 2: AI-Driven Diagnostics: Deploy machine learning algorithms to analyze sensor data and predict specific failure modes with high accuracy (over 90%).

- Level 3: Prognostics: Evolve from predicting failure to predicting the remaining useful life (RUL) of components, enabling just-in-time parts ordering.

- Level 4: Prescriptive Maintenance: The system automatically generates work orders, allocates resources, and orders necessary parts upon predicting a failure.

- Level 5: Digital Twin Integration: Utilize a physics-based digital twin of the asset to simulate complex failure scenarios and optimize maintenance strategies under various operating conditions.

A case study from a large chemical manufacturer perfectly illustrates this potential. By implementing predictive capabilities for its extruders, the company achieved an 80% reduction in unplanned downtime and a 50% reduction in repair cycle time, resulting in estimated savings of $500,000 in a single product line. This demonstrates that PdM is not an expense, but a high-yield investment in operational stability and waste reduction.

To begin your factory’s modernization journey, the next logical step is to conduct a thorough audit of your current processes using the ROI framework outlined. Evaluate your highest areas of ‘process friction’ to identify the investments that will yield the greatest financial and sustainability returns.